Molding (process)

This article needs additional citations for verification. (January 2021) |

Molding (American English) or moulding (British and Commonwealth English; see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix.[1] This itself may have been made using a pattern or model of the final object.

A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material.[2] The liquid hardens or sets inside the mold, adopting its shape. A mold is a counterpart to a cast. The very common bi-valve molding process uses two molds, one for each half of the object.

Articulated molds have multiple pieces that come together to form the complete mold, and then disassemble to release the finished casting; they are expensive, but necessary when the casting shape has complex overhangs.[3][4]

Piece-molding uses a number of different molds, each creating a section of a complicated object. This is generally only used for larger and more valuable objects.

Blow molding is a manufacturing process for forming and joining hollow plastic or glass parts.

A manufacturer who makes molds is called a moldmaker. A release agent is typically used to make removal of the hardened/set substance from the mold more easily effected. Typical uses for molded plastics include molded furniture, molded household goods, molded cases, and structural materials. [citation needed]

Types

[edit]There are several types of molding methods.[5] These include:

- Casting, the oldest term, covering a wide range of materials, especially metals

- Blow molding

- Powder metallurgy plus sintering

- Compression molding

- Extrusion molding

- Injection molding

- Laminating

- Matrix molding

- Rotational molding (or Rotomolding)

- Spin casting

- Transfer molding

- Dry Molded Fiber/Dry molding

- Thermoforming

- Twin sheet thermoforming

- Vacuum forming, a simplified version of thermoforming

- FRP moulding

- Hand lay up moulding

- Resin transfer moulding

- Vacuum bag moulding

- Bladder moulding

- Spray up molding

- Reaction injection molding

Gallery

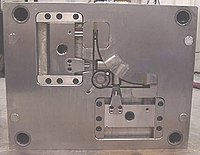

[edit]- Injection molding die with side pulls

- "A" side of die for glass-filled acetal with 2 side pulls

- Close up of removable insert in "A" side

- "B" side of die with side pull actuators

- Insert removed from die

See also

[edit]References

[edit]- ^ "Molding – Definition of molding by Merriam-Webster". merriam-webster.com.

- ^ "Mold – Definition of mold by Merriam-Webster". merriam-webster.com.

- ^ "Articulated mold assembly and method of use thereof". google.com. 14 March 2013. Retrieved 19 March 2018.

- ^ "Articulated molds" (PDF).

- ^ Dean, Yvonne (July 2016). Materials Technology. Routledge. ISBN 9781315504285.

French

French Deutsch

Deutsch